Description

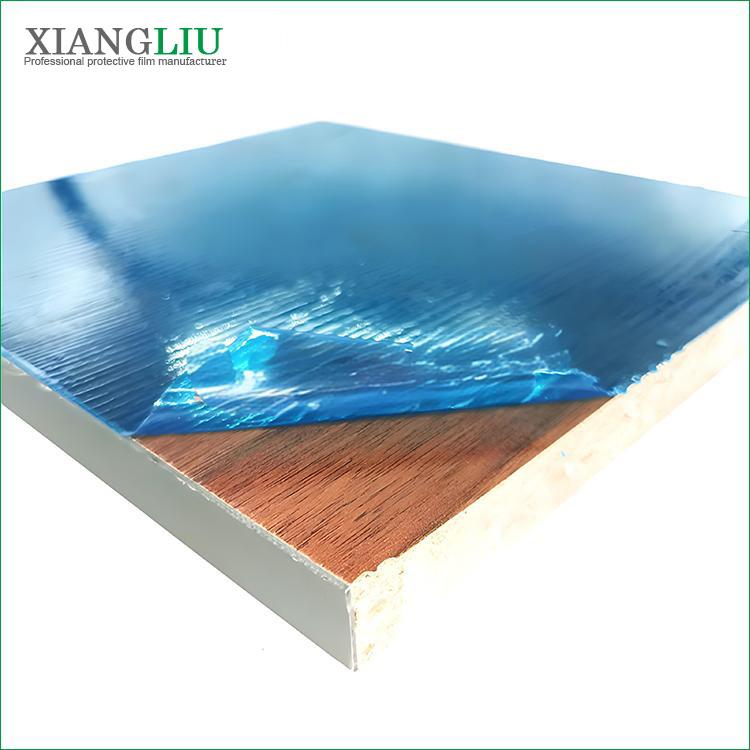

Purification boards are widely used in various fields due to their excellent purification and antibacterial properties. However, to ensure their long service life and maintain their performance, a protective film is often applied.

The protective film for purification boards is made of high-quality materials that are designed to adhere firmly to the surface of the board without affecting its functionality. It provides a physical barrier that protects the board from scratches, abrasions, dust, and other contaminants.

One of the main advantages of using a protective film is that it helps to preserve the appearance of the purification board. The film can be clear or have a matte finish, allowing the natural beauty of the board to show through while still providing protection. This is especially important in applications where the appearance of the board is a key consideration, such as in hospitals, laboratories, and cleanrooms.

The protective film also helps to extend the service life of the purification board. By protecting the surface from damage, the film reduces the need for frequent replacements and repairs, saving time and money in the long run.

In addition to providing physical protection, some protective films for purification boards may also offer additional features such as anti-static properties or UV resistance. These features can further enhance the performance and durability of the board in specific environments.

Overall, a protective film for purification boards is an essential accessory for anyone looking to protect their investment and ensure the long-term performance of their purification system. Whether used in a commercial or industrial setting, a high-quality protective film can help to keep your purification board looking and performing its best.