Description

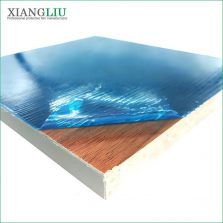

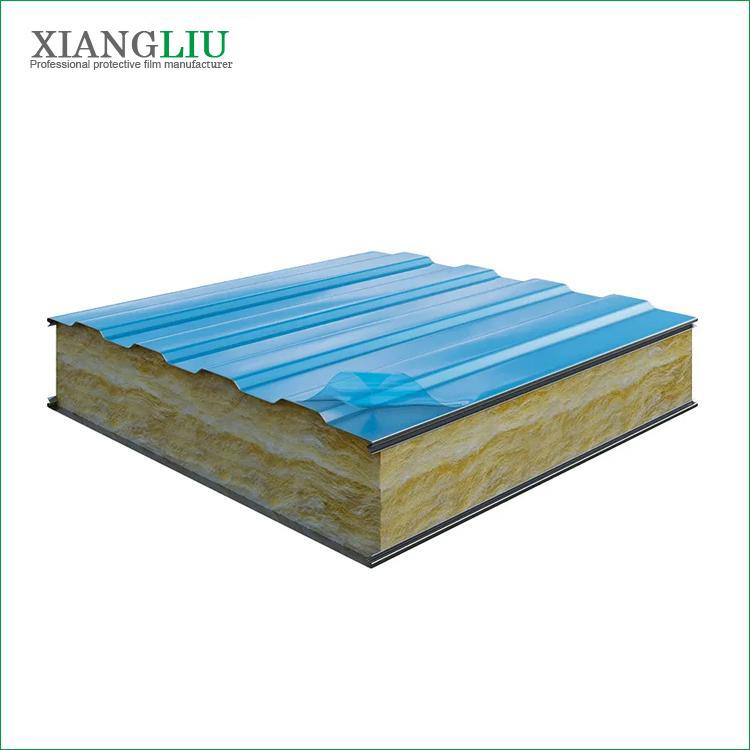

Sandwich panels are widely used in construction and various industries due to their excellent insulation, strength, and lightweight properties. To protect these panels during transportation, storage, and installation, a protective film is often applied.

The protective film for sandwich panels is typically made of high-quality polyethylene or other durable materials. It is designed to adhere firmly to the surface of the panel without leaving any residue when removed.

One of the main benefits of using a protective film is to prevent scratches, abrasions, and other forms of damage. Sandwich panels are often exposed to harsh environments and handling during their lifecycle, and the protective film acts as a shield to keep the surface in pristine condition.

The film also helps to protect against UV rays, which can cause fading and degradation over time. This is especially important for panels that will be exposed to sunlight for extended periods.

In addition to physical protection, the protective film can also provide some level of moisture resistance. This is crucial for maintaining the integrity of the sandwich panel’s insulation and preventing damage from moisture ingress.

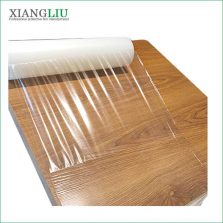

Applying the protective film is a simple and cost-effective way to ensure the longevity and performance of sandwich panels. It can be easily removed when the panel is ready to be installed, revealing a clean and undamaged surface.

Overall, the protective film for sandwich panels is an essential accessory that offers multiple benefits in protecting these valuable construction materials.